The practice of brushing turf has numerous benefits, including healthier plants and improved playing conditions. Photo courtesy of Chip Howard

So, you have heard a lot about brushing turf, but does it actually improve the quality of turf? And if it does, exactly how does it do that? Those are very fair questions, so let’s take a closer look.

If left to the devices of nature, turfgrasses would not be turf. Most grass plants would be knee-high and, except for harvesting seed, would be more valuable to cows than to people. Even bentgrass would have a density of not many plants per square foot.

Rather, leaf blades would be wide (coarse texture) and about 18 inches long. The leaf canopy would resemble an umbrella with leaves oriented in all directions. The leaf canopies would be efficient at intercepting light energy, and because of the tall

plant height, the roots would penetrate deeply for extracting water from deep in the soil profile. Darwin might be proud that the species evolved with this efficient equilibrium that has enabled them to survive in nature. However, it would be fatal

to the career of a superintendent if he/she presented it to members as a putting or fairway surface.

As turf managers, our job is threefold. First, we do unnatural manipulations to grass communities designed to fool the plants into developing a leaf canopy with physical characteristics desirable for ball roll, vertical support, etc. Second, we culture

the grass communities in a way that our patrons find to be visually appealing and ambiance-enhancing. And third, we ensure that the grass communities are consistently in this desirable condition every day and remain healthy.

Career success as a superintendent isn’t as simple as cutting the grass communities short (we can now call it turf). If it were, a goat could be a superintendent. Rather, our job is to push the envelope on the quality of the turfgrass physics and

its aesthetics while keeping it alive and healthy. That said, no two property situations are the same. How far we push quality depends on the objectives, resources and inherent limitations of the property and its environment. How successful we are

at delivering on those objectives also depends on our knowledge, skill and ambition. If you produce superior turf, you should be well paid and soon recruited for a better job. If you deliver inadequate results, you should probably make a career adjustment

before your boss makes the adjustment for you.

Bentgrass seed being harvested. Photo courtesy of Mike Hills

Managing improvement

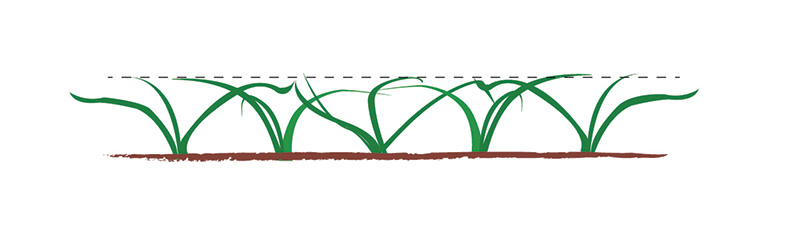

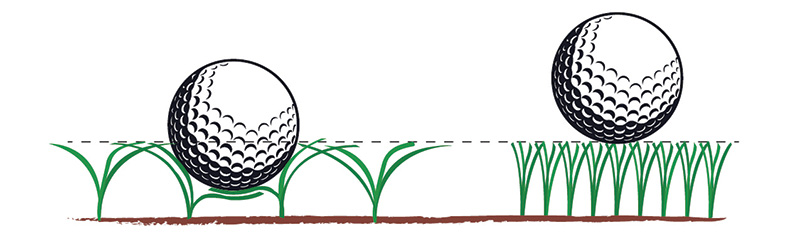

So, what can superintendents do to substantially improve the physics and aesthetics of our turf, with bonus points awarded if what we do is affordable and improves the consistency and health of the turf? Let’s examine a piece of turf as shown in

Figure 1. Whether it is managed at greens or fairway height, the principles are the same.<

Fig. 1

What we see here is a turf where the plant community has adjusted to the cutting height imposed upon it by the person with the mower. The plants are relatively low density with broad, umbrella-like leaf canopies. The leaves have largely diagonal and horizontal

orientations.

Why is that? Unless you are Carl Spackler, who thinks like a gopher, you need to think like a plant. The little imaginary brain inside the grass plant thinks of the leaves as nothing more than biological solar collectors. Just like a solar collector on

your roof, the leaves collect light most efficiently if diagonal or horizontal, not vertical. So, here the plants have arrived at an equilibrium specific to the cutting height (and other factors) where the plant density and leaf configuration is stable.

If we change the cutting height or other factors, the equilibrium will change specific to the new conditions.

In the present condition of our turf, a golf ball that is resting on or moving across that surface of the leaf canopy has the force of gravity pulling it downward. That force is met by physical support from the leaves resisting the downward pull of gravity.

However, the largely horizontal leaves offer little physical support. So, whether the ball is rolling or static, it tends to sink into the leaf canopy. When the ball is rolling, it has to push itself up and over leaves that then compress under the

weight of the ball.

This “vertical deflection” imposed upon the moving ball by the leaves consumes a lot more kinetic energy per foot of travel than it would if it were rolling across a surface with less vertical deflection. The rolling ball is rolling because

it has kinetic energy that was transferred to it by a putter or driver. But as the vertical deflection consumes the kinetic energy, the ball moves slower and slower until the kinetic energy is exhausted. Thus, the greater the vertical deflection imposed

upon the ball by the turf, the quicker it loses speed and the shorter distance it will travel.

I know what you are thinking: “Come on, Mr. Author, please translate all that to English.” Understood. So how about this: The sparser the plant density and the more horizontal the leaf configuration, the slower the green speed or the shorter

the fairway roll.

There is an added dimension with our leaf canopy: When a moving ball impacts a horizontal leaf blade, the leaf imposes a “lateral deflection” upon the ball. The lesser the plant density and the longer the horizontal leaves, the greater the

lateral deflection. This is of particular importance on putting surfaces. Especially when the ball is running out of kinetic energy, the lateral deflection may cause the ball to wobble off-line. May God help the superintendent on the last day of the

televised tournament when the leader’s ball takes a right turn six inches from the cup on the 18th green. The lesser the lateral deflection imposed upon the moving ball, the truer the ball roll.

A greensmower fitted with a front brush, which lifts the blades of turf shortly before they are cut. Photo courtesy of Mike Hills

Setting up for success

At many golf facilities, the turf canopy described above may be satisfactory. If so, that’s great, and the superintendent can grab a towel and head for the pool. But what if by choice or demand you want to improve the play quality of the surface?

Well, it is logical that if we can reduce the vertical and lateral deflection imposed upon the ball, that should help. To do that, we will need to lessen the horizontal leaves and increase the plant density.

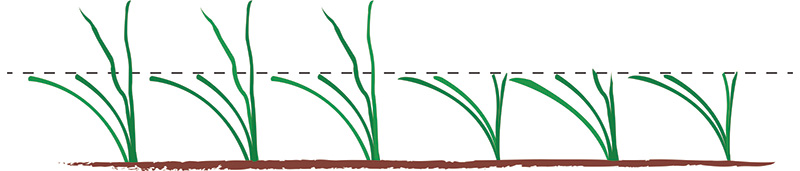

Suppose that one day we mow our turf from right to left, and we put a brush immediately in front of the cutter. As the brush passes over the leaf canopy, it doesn’t damage the leaves but merely lifts the leaf blades that are oriented to the right

(Figure 2A). Then, a fraction of a second later — before the leaf blades have an opportunity to relax and return to horizontal — the cutter scissors the upright leaf blades (Figure 2B). Then tomorrow, we mow from left to right. The day

after that, we mow front to back, followed the next day by back to front. In short order, we have rather naked plants missing the horizontal leaves. The remaining leaves are largely vertical (Figure 3).

Fig. 2A and Fig. 2B and Fig. 3

If we were to stop brushing then, the plants would simply regenerate horizontal leaves and go back to the previous equilibrium. But if we continue brushing, the plants have to adapt to a new equilibrium situation. That little brain in the plant says,

“I’m no longer intercepting the light energy between me and the neighbor like I used to. I’m trying to make horizontal leaves, but that stupid person who comes by every morning with a machine won’t let me. It’s time to

go to Plan B and capture the light before the neighbor beats me to it.” Nature has designed ingenious mechanisms that are the “Plan B” called stolons, rhizomes and, in the case of ryegrass, basal tillering.

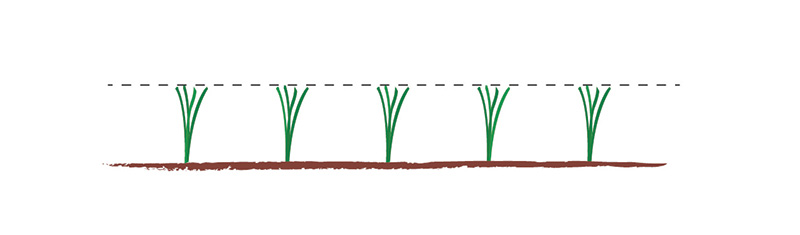

The naked plants make baby plants next door, which increases the density — still with vertical leaf orientation (Figure 4A). The density continues to increase until the plant community arrives at its new equilibrium configuration that reflects the

added imposition of brushing (Figure 4B). At that point, the brain in the plants decides that the light energy is being captured and processed as efficiently as possible, so the density is not increased any further. Of course, any changes in the turf’s

environment, such as changes in cutting height, will cause the equilibrium configuration to change again accordingly.

Fig. 4a and 4b

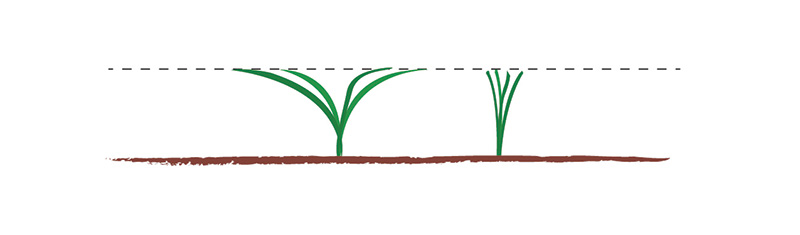

I remember from one of those days that I didn’t skip class in turf school that you should never remove more than a third of the leaf tissue from a turf by mowing or else that plant will be scalped. If the leaves are oriented horizontally at the

top of the canopy, it doesn’t take much of a change in cutting height to blow past the one-third rule (Figure 5). If the leaves are oriented vertically, it would take a drastic lowering of the cutting height to remove a third of the leaf tissue.

Intuitively, we can conclude that brushed turf is more resistant to scalping damage. My customers and I have certainly observed a lack of “scalpability,” even at very short cutting heights.

Let’s extrapolate that thought further. The other day that I didn’t skip class, I remember hearing that the longer the leaf length, the coarser the leaf texture (think of the bentgrass plant in the hayfield versus on a putting green). In the

hayfield, the plant structure is huge compared to that of a putting green even though the plant DNA is identical.

A bentgrass production field. If left to its own devices, turf would grow unabated and be more valuable to livestock than to people. Photo courtesy of Mike Hills

Brushing and beyond

But cutting height isn’t the same thing as leaf length. At any given cutting height, the leaf length of horizontal leaves is much longer than that of vertical leaves. Applying what I heard in class, can we conclude that the leaf texture of brushed

turf is finer than that of unbrushed turf due to its shorter leaf length? If so, the lateral deflection imposed upon a rolling ball is less with a brushed compared to an unbrushed surface, another reason that brushing results in more-true ball roll.

To extrapolate even further, shorter leaf length not only makes the leaf texture finer, but it reduces the texture of the individual plant in general. In other words, reducing the leaf length results in generally miniaturized plants compared to the unbrushed

(Figure 5). That makes the plants even more resistant to scalping as the crowns are closer to the substrate surface.

Fig. 5

In the real world, I have many clients who brush and mow daily at 0.080 inches, and the turf never misses a beat. This tolerance for lower cutting height with less tendency for scalping gives a superintendent a wonderful managerial tool. Even if you don’t

accept that brushing increases ball roll, it gives you the opportunity to change green speed as you wish daily. For example, if you want an extra foot of ball roll on the morning of a tournament, you can reduce the cutting height by perhaps 0.010

inch with no adverse consequences.

Is brushing the only way to modify the configuration of a turf’s leaf canopy as described? No! In fact, plant breeders have dedicated their careers to doing just that. The more modern varieties of bentgrass and bermudagrass have more upright leaf

orientations. That results in a shorter leaf length at a given cutting height. That, in turn, results in miniaturized plants packed closer together with vertical leaves. As a ball rolls across the surface, the leaves provide more resistance to both

vertical deflection and horizontal deflection. In other words, the more modern varieties are able to deliver faster and more-true putting surfaces.

Still not a believer? Visualize an older variety like a Penncross putting surface compared to a more modern one like Pure Distinction, for example. The Penncross leaf configuration may more resemble Figure 6A, whereas the Pure Distinction will resemble

Figure 6B. The same would be true comparing Tifgreen 328 with an ultradwarf bermudagrass putting surface. These selected traits in the product of plant breeding programs are what have enabled putting surfaces to become dramatically faster and smoother

over recent decades.

Fig. 6a and 6b

The Poa factor

So, brushing and/or improved varieties increase plant density with more-vertical leaf orientation. The product is faster, the ball roll is truer, and, in the case of fairways, there is better ball support.

Are there any other advantages to this improved turf canopy configuration? Yes, a really big advantage. Consider a mixed stand of bentgrass/Poa annua in a golf green. Summer favors bentgrass, and winter favors Poa. So, in the annual yin-yang, bentgrass

increases its population by invading Poa territory in warm weather. Conversely, Poa overruns bentgrass in cool weather.

With imagination, we can consider a golf green to be a battlefield with two armies constantly in expansion and retreat. However, Poa is a species of opportunity. If the density of the bentgrass can be seriously increased during good times, it will more

successfully resist re-invasion by the enemy. Hence, increased density by virtue of brushing and/or improved varieties shifts the competitive advantage in favor of bentgrass at the expense of Poa populations.

Does this concept of turf improvement from brushing apply to all turf species and cutting heights? My 30 years of experience dealing with turf brushing has shown me the same results for every cutting height from greens to fairways. Long-cut roughs are

a different creature, although brushing for the purpose of visual striping or uniformity is not unusual. The concept has also given the same results on warm- and cool-season species from the tropics to the far north and around the globe.

Even though the brushing concept works fruitfully in all the circumstances that I have experienced, the managerial application of the brushing varies according to the species and environment. For example, when a turf is slow-growing or even dormant in

the cool season, the superintendent would elect to use a soft brush. Likewise, in seasons when the turf is growing aggressively, he/she would use an aggressive brush, as a soft brush would be ineffective. Medium brushes would be used in the between

times. In other words, a superintendent would switch brushes as appropriate in order to match the aggressiveness of the brushing to the aggressiveness of the turf growth.

Brushing is not a new concept, as the virtue of brushing has been known for decades. For example, I have a Jacobsen advertisement for a front-mounted greensmower brush attachment in a 1946 publication. That said, not all brushes are equal in efficacy.

Although any effort of brushing is good, front-mounted brushes have a distinct advantage. When brushed into a vertical position, leaf blades rather quickly relax and go back to their horizontal position. Behind a front-mounted brush, the cutter arrives

a fraction of a second after the brush and scissors the leaves before they can go back to horizontal. Also, because they become part of the mower, they can be used every time the turf is mowed without any extra equipment or labor.

Does brushing improve the characteristics of the newest high-density varieties? Can brushing improve turf surfaces that are already excellent? Remember the line in the movie “Top Gun”? “You are the top 1% … the elite, the best

of the best. We will make you better.”

Chip Howard, CGCS, CPAg, Ph.D., (turfsci@cox.net) is the owner of TurfScience Inc., a turfgrass consulting business located in Phoenix. The company also manufactures and sells the Transformer Brushing System.