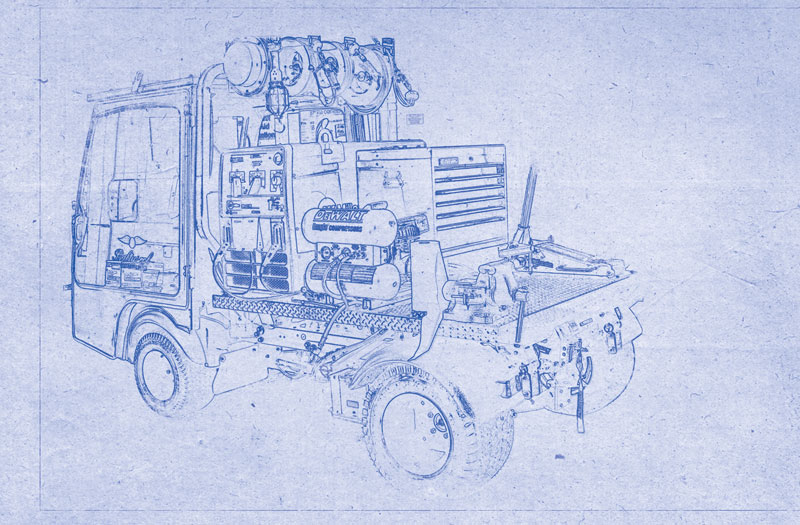

Building your own mobile shop vehicle doesn’t require purchasing new equipment from a manufacturer — you can assemble it over time, adding elements as you go. Photo illustration by Roger Billings

The days of equipment managers getting away with inefficiencies in the way they work are long gone in golf course management. This tightening-up of operations requires them to have the tools needed to do the job in any situation — both in the shop and, maybe more importantly, on the go — so they can keep equipment running in the field. Helping reduce downtime helps everyone, but in order to do that, equipment managers need to outfit their utility vehicles properly to minimize the need to run back and forth to the shop.

Over the years, dedicated carts for equipment managers have not just become popular, they’ve almost become a necessity. The reality for most is they have less time available to get the job done, so having the tools in the field to get equipment back up and running while decreasing trips back to the shop is key.

As an equipment manager myself, the evolution of these carts has been really fun to watch. There are many vehicles that are simple, designed to get just the equipment manager and a few of his tools from point A to point B. Others sport custom hydraulic lifts that have turned them into miniature tow trucks.

Personally, I have had a combination of different types of vehicles during my career, ranging from just a regular Club Car golf cart to a fully customized Toro Workman, both of which had their place. Obviously, the fully outfitted Workman was a great tool for doing repairs in the field, but the electric Club Car made it much easier to get around the course in stealth mode, without disturbing players.

So, what should an equipment manager include if given the opportunity to build one’s own “Ultimate Utility Vehicle”? Because every operation faces different challenges, what to include and what not to include will differ slightly from course to course. However, the following is a list of things that I have either seen on other utility vehicles or included on my own that might help you in putting together the best vehicle for your operation.

The checklist

Toolbox and tools

One of the most irritating things about making repairs in the field is running out on the golf course only to find you don’t have the wrench you need, which means an extra trip back to the shop. So, my first must-have for any equipment manager’s vehicle is a small toolbox loaded with your vital tools. I’d suggest outfitting this with its own set of tools so you aren’t borrowing from the main toolbox every time you head out on the course.

Austin Wright, the equipment manager at Country Club of Leawood (Kan.), reconditioned a 1984 E-Z-Go golf car that had been given to him by his grandfather to use as his primary on-course vehicle. Among his additions were a small storage space for items such as a cup cutter and a portable battery charger and jumper (top left), a complete toolbox, and an air compressor (bottom left). Josh Thomas is superintendent at CC of Leawood. Photo by Roger Billings

Height-of-cut gauge and cutting paper

A common reason many of us get called away from the shop and onto the course is because of equipment getting knocked out of adjustment or maybe just not cutting properly. So, I’ve found that having a height-of-cut gauge and cutting paper with me is essential. This allows me to make minor adjustments on the fly.

Prism gauge

One of equipment managers’ biggest responsibilities is managing quality of cut, so a prism gauge to inspect quality of cut as well as effective height of cut is a great tool to carry along for spot-checking areas on the golf course.

Air compressor and tire patches

This one is a given. Among the most frequent things equipment managers chase in the field is flat tires, usually caused by hitting curbs or running over sticks and such. So, make sure your Ultimate Utility Vehicle has a gas-powered air compressor as well as tire patches so you can take care of flats while in the field rather than having machines limp back to the shop.

Jump box

Another of the most recurrent problems equipment managers deal with in the field is turbine blowers that are no longer charging properly and need to be jumped. If you add this to your vehicle, make sure you have a secure place for storage of the jump box, and make sure it gets charged. I’ve learned from personal experience that you don’t want to be out in the field when you realize that the jump box never got plugged in after its last use.

Winch/tow rope

Unfortunately, another common reason equipment managers get summoned to the course is someone getting stuck in a bunker or a lake. A winch is great if you’re customizing a Workman, a John Deere Gator or similar utility vehicle, because those give you the ability to set the brakes and minimize any damage that can be caused by spinning wheels or the sudden motions from jerking machines out of trouble. But let’s face it: There will still be those times where we will need to run in and fetch the front-end loader for tasks such as these.

Quiet generator

A generator is a valuable piece of equipment to have along with you because it provides you power on the go. Maybe you need to plug in a light early in the morning or use a corded drill, or maybe the irrigation tech needs to use it to vacuum out irrigation boxes.

The John Deere Gator used by Skip Heinz, the equipment manager at Belfair Plantation in Bluffton, S.C. Photo courtesy of Skip Heinz

Welder and torch kit

This may be overkill in many places, but there are multi-course facilities and courses that are spread out with older equipment at which having a welder on the vehicle could come in handy. While a welder would be used most often on a heavy-duty utility vehicle, it may prove useful on many other types. The mini-torch kits, however, are great tools to have regardless of the size of the vehicle you’re working with, especially for when the sledgehammer just doesn’t quite do the trick.

USB plugs

Ten years ago, no equipment manager would have even considered this option. But we are in new times, so creating the ability to charge your cell phone or tablet while on the go is a worthwhile inclusion.

Lights

You may think this would be a given, but you’d be surprised at how many equipment managers’ vehicles don’t have lights. Installing an auxiliary set to shine behind your cart is great, as well, when you have to tow or pull something out in the dark.

Doors, windshield and canopy

Depending on where you’re located, you will be battling different conditions when you’re called out on the course, from snow to rain to extreme heat. And whether that call is to help retrieve a piece of stuck equipment or to clear the course during a severe storm, setting up your vehicle to protect you from such conditions is a wise consideration when planning your ultimate shop cart.

Heater/fan

Something else to think about if you have a vehicle with a canopy or doors is that you will need to cool it during summer, and, if you’re in a region that gets extremely cold, heat it during winter. Just be mindful as you are hooking up these accessories whether your particular vehicle has the capacity to run them all.

Vise

Mounting a vise to the bed of your vehicle will make working on things so much easier. It’s quite often that you get out in the field and realize having another set of hands would be beneficial, and that’s what a vise can provide. It’s also very useful when the need to make some quick irrigation repairs arises.

The Ultimate Utility Vehicle used by equipment manager Kenneth Meals at Baltusrol Golf Club in Springfield, N.J. Photo by Scott Hollister

Jack and jack stand

If there is room, a portable jack and jack stand to assist in changing flat tires would be another great addition to your vehicle. The important thing with this tool is to make sure it’s secure and not rolling around in the bed of the vehicle.

Hydraulic hose machine

Although this isn’t an item you’d typically think of for this type of vehicle, being able to replace a hydraulic hose in the field can also help minimize the downtime of a piece of equipment. Not having one would mean taking off the hose, running it to the shop to build the new hose, and then running it back out. That can all be done on-site as long has you have the fittings needed for the repair.

To each his own

The list here is certainly not all-inclusive, as I have seen a number of different configurations for vehicles such as these, but these are the most common options included. In the future, I could certainly see more items being incorporated as golf equipment evolves. Perhaps a lithium-ion battery will power your vehicle, which should offer an added layer of reliability and quiet operation. Maybe GPS units will become standard, allowing you to track where all of your course’s machines are from the seat of your vehicle. That alone would save the drive time most of us currently endure as we search for a particular piece of equipment.

Building your own mobile shop vehicle isn’t something that requires you to go out and purchase new from an equipment manufacturer. It’s something you can build over time, adding pieces as you go. And whether you start out with one of your course’s older fleet vehicles or are lucky enough to get a new vehicle, don’t rush into modifications. Add things that are really going to help you be more efficient. Having elements on your cart that just “look cool” may not be functional or actually save you any time. Every item should be there because of how frequently it gets used.

The Ultimate Utility Vehicle is certainly something I would recommend for every operation, as you never know when or where you may need to make a repair. Having the right tools at the right time to handle those situations can get your equipment back up and running much more quickly, which will keep maintenance operations moving as they should. So, take a look around your facility, and start deciding what your Ultimate Utility Vehicle will look like.

Stephen Tucker is the equipment manager at the Four Seasons Resort Orlando (Fla.) at Walt Disney World Resort, and the former CEO of the International Golf Course Equipment Managers Association.