Experimental plots of creeping bentgrass (Agrostis stolonifera) being evaluated for infiltration rate after aerification in Stillwater, Okla. Photos by Naba Amgain

Editor’s note: This research was partially funded by GCSAA through a grant from the Environmental Institute for Golf.

Managing soil organic matter and root-zone moisture patterns of sand-based putting greens is critical to long-term health of turfgrasses. Soil compaction and accumulation of organic layers near the root-zone surface reduce infiltration rates, decrease surface firmness, inhibit deep rooting and negatively affect playability (6, 7).

Mechanical cultivation practices such as core aerification, vertical mowing and topdressing are commonly used to maintain desirable root-zone physical properties and reduce organic matter buildup. However, core aerification can reduce the aesthetic and functional aspects of a putting green, temporarily causing reduced revenue or distaste within the course membership. Air-injection and sand-injection cultivation are growing in popularity because they offer a less invasive approach to managing soil physical properties. These new cultivation practices have been reported to increase infiltration and drainage or reduce soil compaction with minimal surface disruption (1, 2, 4).

Combining alternative aerification practices such as spiking, slicing, water-injection cultivation, air-injection cultivation and sand-injection cultivation with core cultivation is becoming popular (1, 3, 5, 6). Although superintendents have shown significant interest in new cultivation technology, there is a lack of unbiased information on the efficacy of novel cultivation practices, especially air-injection and sand-injection cultivation. Uncertainty remains regarding how these practices could be used to complement conventional topdressing and core cultivation methods.

The objective of this research was to evaluate the effectiveness of novel cultivation (air-injection and sand-injection cultivation) and the combination of novel cultivation and conventional cultivation (hollow-tine cultivation) for improving soil physical properties — such as volumetric water content, surface firmness and infiltration rate — and controlling organic matter.

Site conditions and treatments

Two field experiments were conducted from September 2017 to September 2019 at the Oklahoma State University Turfgrass Research Center in Stillwater, Okla., on a 25-year-old Penncross creeping bentgrass (Agrostis stolonifera L.) green constructed on a sand-based root zone.

Experiment I was designed to assess the longevity of effects of single applications of air-injection, sand-injection and hollow-tine cultivation. Experiment II was designed to compare the effects of novel cultivation practices (air-injection and sand-injection cultivation) alone or in combination with conventional (hollow-tine) cultivation on soil physical properties, including volumetric water content, surface firmness, infiltration rate, ball roll distance and organic matter.

Air injection resulted in negligible surface disruption on the Oklahoma State University research green in Stillwater, Okla.

A sand-injection treatment applied using the DryJect.

The green was mowed daily during the growing season at 0.150 inch (3.8 millimeters), with clippings removed. Fertilizer was applied to achieve an annual rate of 5 pounds nitrogen/1,000 square feet (24.4 grams/square meter). Topdressing was applied biweekly to all plots during the growing season at a rate of 2.6 cubic yards/acre (4.9 cubic meters/hectare) using a locally available kiln-dried sand that met USGA specifications for root zones. A wetting agent was applied monthly from June to August each year in accordance with typical practices to reduce localized dry spot. The experiment station’s standard fungicide and insecticide programs were applied to prevent common diseases and insects.

Air-injection cultivation was applied using the Air2G2 (GT AirInject Inc.). The air-injection cultivation equipment was operated at an injection-burst pressure of 50 pounds/square inch (345 kilopascals) through a 9-inch-long (22.9-centimeter-long) tine and a tine-insertion pressure of 50 pounds/square inch on 23.5- × 23.5-inch (60- × 60-centimeter) spacing. Sand-injection cultivation was accomplished using the DryJect (DryJect Inc.) on 3- × 2-inch (7.6- × 5-centimeter) spacing at a 4-inch (10-centimeter) tine depth.

Hollow-tine cultivation was applied using a walk-behind aerifier (ProCore 648, The Toro Co.) equipped with 0.5-inch (1.3-centimeter) outside-diameter and 2.5-inch-long (6.4-centimeter-long) tines set at a 2- × 2-inch (5- × 5-centimeter) spacing. Sand used for sand-injection and hollow-tine cultivation was the same material previously described for topdressing.

Data collected

Infiltration rates were measured using a double-ring infiltrometer (6- and 12-inch [15.2- and 30.5-centimeter] rings) and the falling-head technique (3). The rings were inserted approximately 2 inches into the soil surface. Water was added to the top of both rings. Infiltration rate was recorded as the decrease in water within the inner ring after 10 minutes. The process was repeated until two consecutive readings were the same.

Surface firmness was measured using a handheld firmness meter (FieldScout TruFirm, Spectrum Technologies) that records the penetration depth of a falling plunger as it hits a surface. Volumetric water content (3-inch [7.6-centimeter] depth) was measured using a handheld soil moisture meter (FieldScout TDR 300, Spectrum Technologies).

Ball roll distance was measured using a 14-inch-long (35.6-centimeter-long) modified Stimpmeter. The distance measurements for six rolls were averaged to obtain a single value for each experimental unit.

Organic matter was measured in the upper 2 inches (5 centimeters) using the loss-on-ignition method. The percent recovery from a cultivation event was estimated visually on a scale of 0% to 100% (100% = holes fully recovered) (1). Recovery was rated seven, 14 and 21 days after treatment.

Turf cultivation Experiment I: Single-event longevity experiment

Because we could not always apply treatments on the same day, cultivation type (air-injection, sand-injection or hollow-tine cultivation) was analyzed separately in comparison with a control plot measured on the same date. Measurements were made 24 hours prior to a cultivation event and subsequently seven days, 14 days, 21 days and 28 days after treatment.

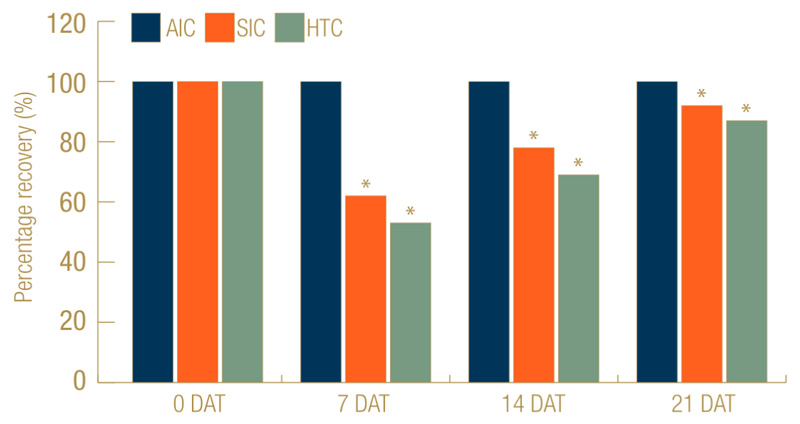

Figure 1. Effect of cultivation type on percentage recovery at 0, 7, 14 and 21 days after treatment (DAT) on a creeping bentgrass putting green in Stillwater, Okla. AIC = air-injection cultivation (Air2G2, GT AirInject Inc.); HTC = hollow-tine cultivation (ProCore 648, The Toro Co.); SIC = sand-injection cultivation (DryJect, DryJect Inc.). *Significantly different from control.

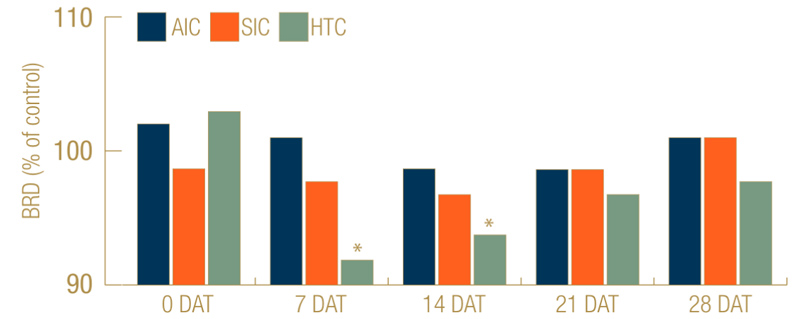

Figure 2. Effect of cultivation type on ball roll distance (BRD) at 0, 7, 14, 21 and 28 days after treatment (DAT) on a creeping bentgrass putting green in Stillwater, Okla. Data are expressed as percentage of control. AIC = air-injection cultivation (Air2G2, GT AirInject Inc.); HTC = hollow-tine cultivation (ProCore 648, The Toro Co.); SIC = sand-injection cultivation (DryJect, DryJect Inc.). *Significantly different from control.

Air-injection cultivation maintained visual coverage similar to that of the non-cultivated control (Figure 1). Hollow-tine cultivation treatments were 87% recovered, while sand-injection cultivation treatments were 92% recovered at 21 days after treatment. Similarly, ball roll distances for air-injection and sand-injection cultivation were similar to the untreated control. Hollow-tine cultivation reduced ball roll distance up to 14 days after treatment compared with the untreated control (Figure 2). The reduced injury and unaffected ball roll distance associated with air-injection and sand-injection cultivation highlight that each technique has the potential to sustain revenues for golf facilities concerned about the disruption associated with hollow-tine cultivation.

No significant treatment effect was observed for soil volumetric water content. We speculate that the lack of difference in volumetric water content after cultivation is related to the inherently good infiltration rates of the site and our inability to irrigate plots differentially. The infiltration rates ranged between 10 and 15 inches (25.4 and 38 centimeters)/hour for the untreated control, which is higher than the USGA-recommended minimum infiltration rate of 6 inches (15.2 centimeters)/hour.

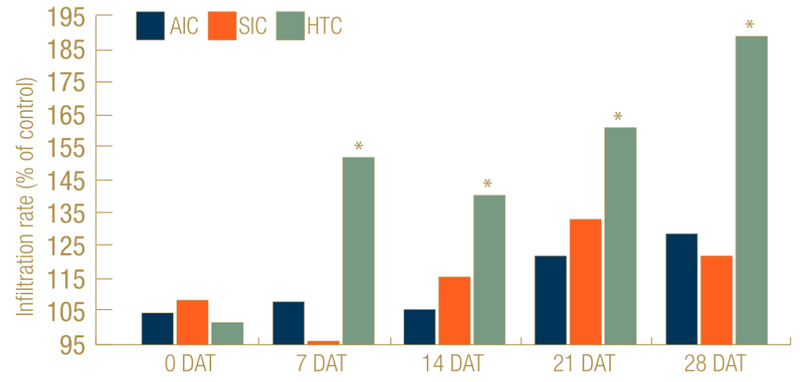

The only cultivation treatment that increased infiltration rate was hollow-tine cultivation, which had an 87% higher infiltration rate than the untreated control 28 days after treatment (Figure 3, below). Although each cultivation treatment created vertical channels through the surface, air-injection and sand-injection cultivation each had smaller holes, larger spacing and an overall lower area affected than hollow-tine cultivation. Despite this, we were surprised to see no difference among air-injection cultivation, sand-injection cultivation and the untreated control.

Figure 3. Effect of cultivation type on infiltration rate at 0, 7, 14, 21 and 28 days after treatment (DAT) on a creeping bentgrass putting green in Stillwater, Okla. Data are expressed as percentage of control. AIC = air-injection cultivation (Air2G2, GT AirInject Inc.); HTC = hollow-tine cultivation (ProCore 648, The Toro Co.); SIC = sand-injection cultivation (DryJect, DryJect Inc.). *Significantly different from control.

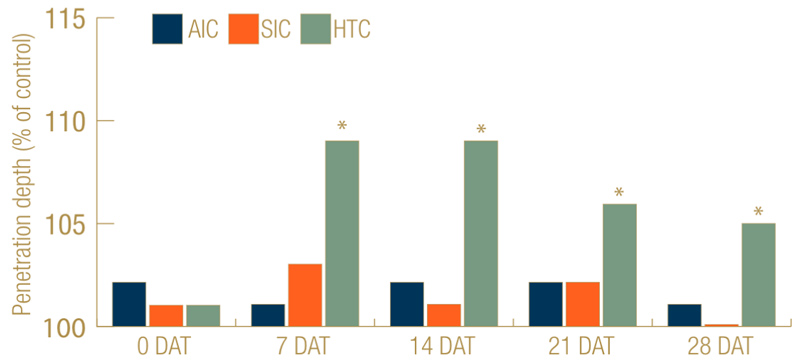

Figure 4. Effect of cultivation type on penetration depth (surface softness) at 0, 7, 14, 21 and 28 days after treatment (DAT) on a creeping bentgrass putting green in Stillwater, Okla. Data are expressed as percentage of control. AIC = air-injection cultivation (Air2G2, GT AirInject Inc.); HTC = hollow-tine cultivation (ProCore 648, The Toro Co.); SIC = sand-injection cultivation (DryJect, DryJect Inc.). *Significantly different from control.

The only cultivation treatment that affected surface firmness was hollow-tine cultivation, which had a 5% softer surface compared with the untreated control 28 days after treatment (Figure 4). Holes created after hollow-tine cultivation provide additional space for collapsing the side walls, which likely contributes to the playing surface becoming soft (8). This is not surprising considering hollow-tine cultivation was intended to be the most disruptive form of cultivation. However, we were again surprised that neither air-injection cultivation nor sand-injection cultivation had any effect on firmness in the short term.

Organic matter ranged from 2.29% to 2.44% in the upper 2.5 inches (6.4 centimeters), but none of the cultivation events reduced organic matter compared with the control. The lack of any cultivation treatment effect on organic matter content in the present study may be attributed to the small surface area of impact, the duration of the experiment and inherent difficulty in sampling. Furthermore, the regular topdressing sand applied to all plots, including the control, may have also contributed to the inability to detect a difference in organic matter. The USGA recommends impacting 15% to 20% of the surface area yearly to manage thatch-mat and soil organic matter (9). In contrast, hollow-tine cultivation and sand-injection cultivation events applied in the present study only impacted 4.9% and 3.3% of surface area, respectively.

Turf cultivation Experiment II: Annual program experiment

All measurements were made within 24 hours before a cultivation event and subsequently at one, two, three and four weeks after treatment, and monthly thereafter. In order to simplify the interpretation of Experiment II, data were averaged for each year prior to analysis. On an annual basis, surface firmness, ball roll distance and organic matter content were unaffected by cultivation treatment.

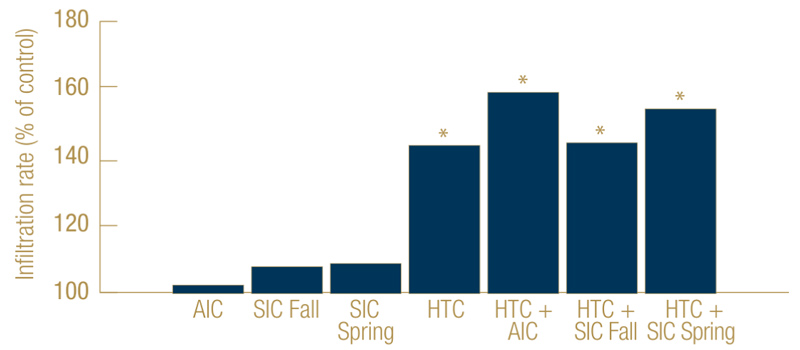

Figure 5. Effect of novel cultivation practices using air injection (AIC) or sand injection (SIC); conventional cultivation practices using hollow-tine core aerification (HTC); or a combination of novel and conventional cultivation practices on annual mean infiltration rates on a creeping bentgrass putting green in Stillwater, Okla. Data are expressed as percentage of control. AIC = air-injection cultivation (Air2G2, GT AirInject Inc.); HTC = hollow-tine cultivation (ProCore 648, The Toro Co.); SIC = sand-injection cultivation (DryJect, DryJect Inc.). *Significantly different from control.

Annual mean infiltration rates were affected by cultivation type such that any treatment with hollow-tine cultivation had higher infiltration rates than those without hollow-tine cultivation (Figure 5). Interestingly, the combination of hollow-tine cultivation with air-injection cultivation further enhanced the infiltration rate over hollow-tine cultivation alone. Despite this, there was no evidence that air-injection cultivation alone increased infiltration rates over the untreated control.

These findings suggest air-injection cultivation alone provides a synergistic effect with other cultivation events having higher surface disruption, but the 2-foot (60-centimeter) spacing between holes limits effects when used alone. We saw further evidence of this when measuring infiltration rates at a local golf course. Measurements taken directly over a hole created by air-injection cultivation showed a 51% greater infiltration rate than pre-cultivation measurements, but there were no changes in pre-cultivation and post-cultivation measurements at a spot adjacent to the hole.

Implications for use of sand-injection cultivation

Although results of the present short-duration studies suggest minimal benefit from using sand-injection cultivation, we recognize several limitations of our experimental design. For example, we limited the studies to using USGA-recommended sand as the injection media because this was the most common practice in our region. As sand-injection cultivation technology has evolved over the past few years, superintendents have begun injecting a variety of sands and soil amendments, which likely would have different effects than straight sand.

Right: A soil profile after sand injection via the DryJect.

Furthermore, the experimental site was originally built with a coarse sand particle size distribution, and, although cultivation had been curtailed for the year prior to this study, the site had received routine cultivation over the past 20 years. Evaluation of sand-injection cultivation on root zones with severe layering issues, finer sand particle size distributions, or that otherwise have some compromising issues may have been a better test for the technique.

Finally, we recognize that a number of machine configurations are available that could have been used to increase the aggressiveness of sand-injection cultivation and the amount of sand injected. Again, the settings used in the present study were chosen based on typical practices in our region. Dilution of organic matter is expected to be an important function of sand-injection cultivation, and we speculate a longer-duration study or more aggressive settings would have shown this response.

Implications for use of air-injection cultivation

Using air-injection cultivation alone did not influence most measurements made in either of these studies. However, incorporation of air-injection cultivation with hollow-tine cultivation showed promise for further enhancing infiltration rates over hollow-tine cultivation alone. We speculate that use of air-injection cultivation may be most beneficial if used in conjunction with other forms of cultivation that perforate the surface. Although not tested in this study, common practices such as needle-tine cultivation may be less invasive than hollow-tine cultivation but still effective in creating the surface perforation needed to supplement air-injection cultivation.

Editor’s note: A turf scientist outlines the different cultivation techniques to help you determine the best regimen for your site in Turfgrass cultivation methods: A roster.

In conclusion, neither air-injection cultivation nor sand-injection cultivation alone showed any consistent effects in regard to soil moisture, surface firmness, organic matter or infiltration rate. These results suggest a continued need for hollow-tine cultivation as a staple in golf agronomic programs. Incorporation of these novel technologies should be done to supplement hollow-tine cultivation and with specific management goals in mind.

Funding

We greatly appreciate the financial support from GCSAA, the Environmental Institute for Golf and the Oklahoma Turf Research Foundation.

Acknowledgments

We also wish to thank our cooperators who applied cultivation treatments in these studies, including Sean Hogan, Gaillardia Country Club, Edmond, Okla.; North Texas & Oklahoma DryJect; and Mike Buxton, CGCS, Lakeside Memorial Golf Course, Stillwater, Okla.

The research says ...

- Air-injection and sand-injection cultivation have been reported to increase infiltration and drainage or reduce soil compaction with less surface disruption than hollow-tine cultivation.

- In this research, neither air-injection nor sand-injection cultivation alone showed consistent effects in regard to soil moisture, surface firmness, organic matter or infiltration rate.

- The results suggest hollow-tine cultivation should remain a staple of golf agronomic programs.

Literature cited

- Craft, J.M., C.M. Baldwin, W.H. Philley, J.D. McCurdy and B.R. Stewart. 2016. Impact of dry-injection cultivation to maintain soil physical properties for an ultradwarf bermudagrass putting green. HortScience 51(9):1171-1175 (https://doi.org/10.21273/HORTSCI11018-16).

- Dickson, K., J. Sorochan, G. Munshaw and A. Thoms. 2017. Comparison of cultivation methods impact on playability of Agrostis stolonifera greens. Journal of Testing and Evaluation 46(3):1256-1260 (https://doi.org/10.1520/JTE20160419).

- Fontanier, C.H., K. Steinke, J.C. Thomas and R.H. White. 2011. Effects of venting aeration on neglected bermudagrass putting greens. Applied Turfgrass Science 8(1):1-8.

- Green, R.L., G.J. Klein and L. Wu. 2001. Summer cultivation increases field infiltration rates of water and reduces soil electrical conductivity on annual bluegrass golf greens. HortScience 36:776-779 (https://doi.org/10.21273/HORTSCI.36.4.776).

- Karcher, D.E., and P.E. Rieke. 2005. Water-injection cultivation of a sand-topdressed putting green. International Turfgrass Society Research Journal 10:1094-1098.

- McCarty, L.B., M.F. Gregg and J.E. Toler. 2007. Thatch and mat management in an established creeping bentgrass golf green. Agronomy Journal 99(6):1530-1537. doi:10.2134/agronj2006.0361

- Moeller, A., and T. Lowe. 2016. Managing organic matter in putting greens. USGA Green Section Record 54(21):1-9.

- Murphy, J.A., and P.E. Rieke. 1994. High pressure water injection and core cultivation of a compacted putting green. Agronomy Journal 86(4):719-724 (https://doi.org/10.2134/agronj1994.00021962008600040025x).

- O’Brien, P., and C. Hartwiger. 2003. Aeration and topdressing for the 21st century. USGA Green Section Record 41(2):1-7.

Charles Fontanier is an assistant professor and Naba Amgain was a doctoral student in the Department of Horticulture and Landscape Architecture at Oklahoma State University, Stillwater, Okla. Amgain is currently a postdoctoral researcher at the University of Florida-Everglades Research & Education Center, Belle Glade, Fla.