This trim is going to take a while. Image by Denis Tabler/Shutterstock

If you’ve been in the golf course maintenance industry for any length of time, either as an equipment technician or golf course superintendent, you’ve surely had your share of discussions about how to set up a reel mower for cutting. However simple or complex you believe the reel mower to be, the golf course environment continues to push the envelope when it comes to harnessing cutting efficiency and the quality that can be produced.

Based on your training and personal experience setting up a reel mower, you have likely developed methods you feel confident supporting. This article is not intended to change those methods, nor do I have everything figured out when it comes to cutting grass with a reel mower. After 17 years in the business, I simply wish to provoke thought by discussing the facts surrounding the million-dollar question: “Is a reel mower a scythe or a pair of scissors?”

The scythe theory

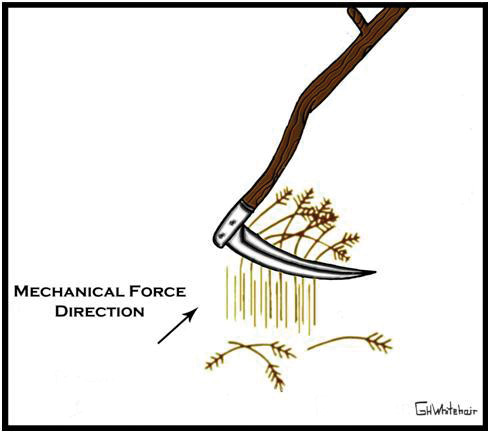

As I have always understood it, the scythe theory would have us believe that if you were to remove the bedknife from a reel mower, it would continue to cut grass to some degree. In other words, like a scythe that is swung across the grass blades, each blade of a reel mower sweeps across the grass with enough speed and force to fracture the grass blades without the mechanical support of a bedknife. Therefore, contact between the reel and bedknife wouldn’t be necessary to cut grass.

The scythe theory maintains that contact between reel and bedknife is unnecessary because the blades of a reel mower sweep across grass like a scythe, with enough speed and force to break the grass. Illustrations and photos courtesy of Brian Whitehair

I have actually tried this myself and gotten absolutely zero cut clippings in the bucket. You may have tried this and seen different results, but it can’t be overlooked that a scythe works with the cutting edge of the blade perpendicular to the standing grass. The blades in a reel mower meet the grass in a more parallel position at the point of clip. Even if the blades in a reel mower were positioned at a 90-degree angle to the standing grass, I strongly doubt this would produce much of a cut without the bedknife. Regardless, that’s not how reel blades are positioned in a reel mower.

The scissors theory

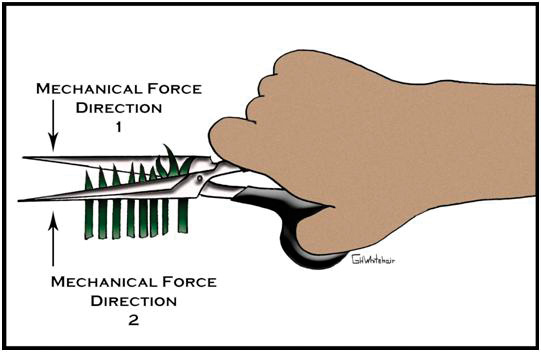

The opposing scissors theory is a simple concept: Like a pair of scissors that has two blades with friction between them during the cutting process, a reel mower has a bedknife, which makes up one half of the scissors blade, and a reel blade (there are actually many blades, but consider only one at a time), which makes up the other half of the scissors. Scissors that have been loosened over time at the hinge pin can develop a gap between the two blades and will not cut very well, if at all, without continual friction. Like scissors, the reel mower cannot cut without contact between the reel blades and bedknife.

The scissors theory holds that the bedknife and reel blade function like the two blades on a pair of scissors, employing angle and friction to cut grass.

Taking the scissors theory even further is the belief that if you run contact between the reel and bedknife, the continual metal-to-metal contact will make the mower self-sharpening. Those who support this idea say that if you do not run contact, you are only using half the mower’s cutting ability, which in turn dulls the reel blades prematurely. Not running contact takes the bedknife out of the cutting action — like scissors minus a blade — and leaves the reel blades to do all the work. But this point of the scissors theory seems a little contradictory, in the sense that proponents do not believe the reel mower is like a scythe.

Many techs who don’t run contact are typically believers in the scythe theory, and those who prefer to run a little contact between the reel and bedknife probably adhere to the scissors theory. As a general rule, I don’t set contact between the reel and bedknife on reel mowers during setup. Does that mean that I think a reel mower is like a scythe because I try to maintain a 0.001-inch to 0.002-inch air gap between the reel and bedknife? No, not any more than it means I believe a reel mower cuts like a pair of scissors.

The reel mower theory

In my opinion, a reel mower is its own entity. The only thing the scythe, scissors and reel mower have in common while cutting is overcoming the friction forces of the object being cut. There are mechanical forces at work in a reel mower that do not exist in the scythe or scissors.

As the reel mower travels forward, it uses the bedknife face to create forward mechanical force, leaning/pushing the grass forward into the oncoming reel blades. The reel blades themselves travel in the opposite direction of the bedknife, creating opposing mechanical force, gathering and cutting the grass as it travels across the cutting edge of the bedknife. The front face of the bedknife, which is behind the grass blades while cutting, also creates upward support — not unlike the vacuum in a rotary mower deck, which is created by a sail on the end of the blade that causes “lift,” or upward mechanical support, of the grass.

The scythe cuts without the addition of mechanical support. To fracture the grass, the scythe relies on the inert force of the grass blades, or leaf tissue, to oppose the mechanical force of the blade.

Unlike scissors, a reel mower will cut efficiently if you maintain a minimal air gap between a sharp reel and bedknife. However, there are valid points that cannot be overlooked when likening a pair of scissors to a reel mower. They use similar mechanical force, regardless of whether you run contact between the reel blades and bedknife. If you sharpen a reel and bedknife, set contact between them and turn the reel by hand, it will cut paper just like scissors.

Where the scissors theory starts to crumble for me is that a reel mower wasn’t designed to sit on a bench and have the reel rotated by hand. During mowing, it must encompass reel velocity, forward motion and bedknife support.

The evolution of the reel mower

It’s easy for me to imagine that, many years ago, mowers were set up with contact between the bedknife and reel in the manner of a pair of scissors. The reel mower has existed for a very long time, as far back as 1825 according to Knight’s American Mechanical Dictionary. The first reference to anything resembling the reel mower reads, “1825: Ten Eyck had a horizontal cylinder, with spiral knives cutting against straight edges. The same was shown by Budding in 1830.”

There is no image showing exactly what Eyck’s machine involved, nor does the entry use the term “scissor.” It does refer to “cutting against,” which I believe means there was contact or friction between the cutting components. It also references Budding, undoubtedly the Englishman Edwin Budding, who in 1830 patented the reel mower design we use today.

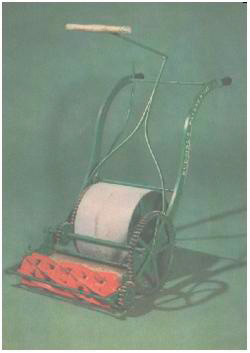

Right: Without the machine accuracy used today to set up a reel mower, metal-to-metal contact may have been a necessity on older models.

As an equipment manager in the modern world of golf, I can’t put a lot of stock into how Eyck or Budding intended the reel mower to cut in the 1800s. We have to consider the evolution in the way we use reel mowers today, along with our sharpening equipment, which allows us to sharpen on a daily basis if we wish.

Metal-to-metal contact between the reel and bedknife could have been more of a necessity than a preference in the past. The reel rotating against the bedknife, with the grass as lubrication between the two, would have been the most effective and practical method for the time and circumstances. In addition, the reels had fewer blades to make contact with the bedknife. In the early days of the reel mower, there were perhaps four or five blades, while today we have anywhere from five to 14 blades available in a greens mower reel.

The bedknives, which take the brunt of the abusive friction when running contact between the reel and knife, were once very thick. This allowed the bedknife to better absorb and transfer the heat generated by the metal-to-metal contact. The newer, thinner bedknives cannot absorb and transfer heat buildup so readily without warping the knife. These thinner knives also limit our ability to apply much front face to the knife. Even though fairway mowers continue to use the somewhat thick knives, 11-bladed reels are becoming more commonplace and create elevated friction between the reel and bedknife.

Angles and accuracy

Today, when setting a reel mower with heavy contact between the reel and bedknife, I can’t afford to overlook the angles we so meticulously apply to the bedknife when we sharpen it — particularly in the lower-cut creeping varieties of grass, which are more susceptible to lateral growth and require the front-face angle to set up the grass blades.

To better comprehend the importance of angles in relation to a cutting tool and the object to be cut, think about common scissors. We’ve all experienced the pinching that happens when you position a scissors’s cutting blades at somewhat of a parallel or improper angle to the object being cut. This pinching may also be caused by dull cutting blades or improperly adjusted blades, or it may be because the material is simply too dense for that particular pair of scissors. Often the quick fix is simply to reposition the scissors blades so they are perpendicular to the material being cut.

It is very important that the bedknife in a reel mower be allowed to remain in its proper condition during mowing for this setup of the grass blades to happen. During the early days of reel mower use on golf courses, cutting heights were higher, sharpening methods were limited, and golfers may have been more accepting of the playing conditions the course provided.

Right: Older versions of the reel mower had only four or five blades, compared with today’s designs, which can have anywhere from five to 14.

I have to wonder how much concern there was all those years ago about mechanical stress to the grass. Early users may have run friction between the reel and bedknife as a compensation for dullness or flaws along the cutting edges. If we are still running contact today, whether it’s to compensate for dullness or for imperfections in the knife or reel, we are creating additional mechanical stress in the grass plant. You cannot compensate for dull scissors blades by increasing the degree of friction between the cutting blades; the answer is to re-sharpen the blades.

I don’t believe the quality of cut we produce today could have been achieved when the design was first conceived. Was the reel mower ever intended to cut grass with a bench setting of 0.080 inch or lower? It’s not likely, as there weren’t any turfgrasses that could have survived at that cutting height. To cut at a height of 0.080 inch, there is limited room for error. Our bedknives have to be maintained with machined accuracy. In the early days of reel mowers — whether on a golf course, sports field or lawn — technicians didn’t have the tools and resources to maintain accuracy on a daily basis.

Today, reel mower manufacturers are producing some very high-quality machines for golf courses. Manufacturers may have differing opinions on the scythe vs. scissors debate, as the two require different setup specifications — even though, as far as the reel and bedknife are concerned, the designs are very similar to the original machines and to each other. The grinder manufacturers also don’t seem to share a common view on the subject. All the different philosophies among equipment manufacturers, grinding equipment manufacturers, technicians, superintendents and anyone else with an opinion can create an aura of mystery around the reel mower.

For me, a reel mower is what it is: a machine that consists of a power plant, a reel, a bedknife and a frame assembly, all harnessing mechanical forces that neither the scythe nor the scissors possess. Power plants and drive systems continue to improve with advances in modern technology, but the heart of the reel mower remains a cylindrical reel of various blade quantities and a bedknife. Kudos to those who try to reinvent or improve reel design, such as Bush Hog’s V-Reel or Toro’s backswept reel, but it’s the original design that has stood the test of time.

In the hands of today’s manufacturers and technicians, we could be harnessing nearly every ounce of efficiency a reel mower can produce, which I don’t believe could have been accomplished in the early days of the reel mower — regardless of whether it was intended to be scythe or scissors.

Brian Whitehair is the turf equipment manager at The River Club in Suwanee, Ga.