Photos courtesy of PBI-Gordon

Fungicides have been used widely in the golf course industry for more than 100 years, since the Bordeaux mixture was first used to control brown patch at the Arlington Turf Gardens, located between Arlington National Cemetery and the Potomac River, in 1917. Over the past century, many fungicide groups with a variety of modes of action have been developed by research scientists.

The types of active ingredients have evolved throughout those years, starting with elements such as mercury, copper and arsenic. Heavy metal fungicides gave way to site-specific fungicides, which were less toxic. These new fungicide groups, in many ways, were as exciting to the turf world as Chuck Connors firing off his Winchester Model 1892 at the start of the iconic TV show “The Rifleman.” The products stopped their pathogenic target in a similar way to Chuck — with a lethal shot to a specific spot in the metabolic pathway.

The first of these “Rifleman” fungicides, the benzimidazoles, were brought to market in the 1960s, followed by the dicarboximides, and then the DMIs in the 1970s. In the years that followed, other notable fungicide groups — such as the SDHIs, phenylamides and the QoIs — were introduced and widely used. With the exception of the phenylamides, all offered broad-spectrum disease (pathogen) control.

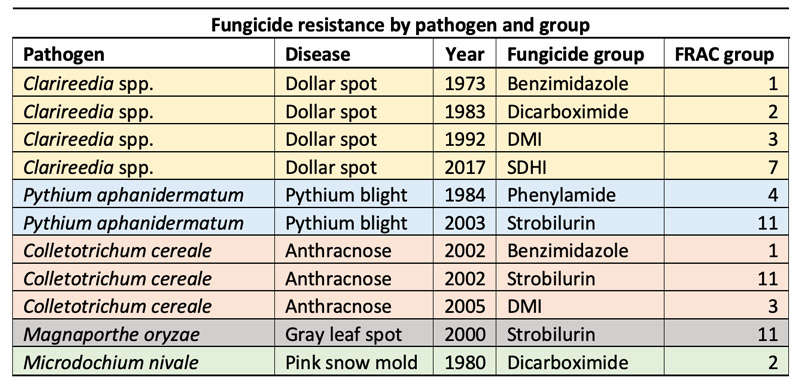

Unfortunately for resistance management, over time these site-specific active ingredients were not always as lethal as Connors’ 1892, as pathogen resistance would quickly develop following the introduction of each of these fungicide groups. Benzimidazole resistance was first documented in 1973 and dicarboximide resistance in 1980, and, in later years, resistance for other groups followed suit.

The following turfgrass pathogens have documented cases of resistance to at least one group of fungicides: Clarireedia spp. (dollar spot), Colletotrichum cereale (anthracnose), Pythium aphanidermatum (Pythium blight), Magnaporthe oryzae (gray leaf spot), and Microdochium nivale (pink snow mold). The year in which resistance was first documented is listed below by pathogen and fungicide group.

In talking with golf course superintendents who worked in the industry during this period, while they agreed that the influx of newer and safer fungicides was exciting, they thought tougher times were on the horizon with the increasing prevalence of pathogen resistance.

Mark Kuhns, CGCS, who most recently served as director of grounds at Baltusrol Golf Club in Springfield, N.J., from 1999-2019 and is now with Turco Golf, says of that time period, “With all the new systemic fungicides, there was a strong desire to increase spray intervals far beyond the shorter interval provided by chlorothalonil, which new products on the market provided. They were also much safer for the environment. But around 2000, we were worried there weren’t going to be new products coming to market. Thanks to the R&D efforts from industry and the advent of premix products, superintendents were able to adapt to increasing resistance issues.”

To be fair, there is no specific point at which resistance became the norm that it is today. Rather, there was a transition over time where fungicide resistance saw an increase in the number of pathogens that developed resistance as well as in the number of groups that became compromised. Before diving into the state of resistance today, it is important to revisit some general plant pathology to understand why resistance happens.

First, fungicides are used to control the pathogen; the pathogen is what causes a plant to exhibit disease symptoms because of a continual irritation or attack in the presence of conducive environmental conditions.

Resistance of pathogens affecting turfgrass is not limited to true fungi, but also includes fungal-like oomycetes (i.e., Pythium spp.). The commonality in the pathogens that have developed resistance is that they either reproduce quickly via the production of an abundance of propagules such as spores or mycelia, and/or they reproduce where sexual reproduction allows for the exchange of genetic material.

The predominant cause of resistance in turfgrass pathogens is due to a target site (binding site) alteration. Therefore, repeated applications with an active ingredient that targets a specific site in the metabolic pathway will eventually result in the pathogen adapting to that active ingredient (or even to that group of fungicides).

The development of an integrated pest management (IPM) strategy is an important method whereby the use of synthetic pesticides is not eliminated, but rather their use is incorporated alongside cultural practices to try to break the disease triangle (host, pathogen and environment) to reduce the overall use of pesticides. However, even with an IPM approach, fungicide resistance continually evolves.

Initial symptoms of Pythium blight.

In an effort to combat pathogen resistance to chemical control measures, plant pathologists formally developed the Fungicide Resistance Action Committee, or FRAC, in 1981. Since its formation, FRAC has provided resistance management guidelines and updates through a variety of publications, including an annual report that lists the current active ingredients by mode of action, target site, group name, chemical group, common name and FRAC group number. Additionally, each group is given a designation on the likelihood of resistance development. While trade names are not provided because the active ingredients listed span various commodities, any turfgrass manager can access this information by visiting www.frac.info to determine the risk level for the active ingredient they are choosing to apply.

Fungicide labels list the FRAC code for each active ingredient in a given product at the top of the label. This allows for ease in determining which fungicide groups are being used with each application.

In addition to being vigilant as to which fungicide groups are included in a spray program, the following suggestions should be helpful in delaying the development of pathogen resistance to fungicides:

- Use IPM practices to break the disease cycle, such as: planting resistant cultivars or non-hosts, fertilizing to prevent or reduce the severity of stress-related diseases, increasing mowing heights, and improving drainage and air movement.

- Site-specific fungicides from the same FRAC group should not be used in more than two consecutive applications. This rule of thumb holds true even when using premix products.

- Use multisite fungicides whenever possible, as they have low to no risk for resistance.

- Incorporate phosphites, SAR (systemic acquired resistance) or ISR (induced systemic resistance) products into the disease management program.

The advent of site-specific fungicides has provided turfgrass managers with an abundance of products from which to choose. It cannot be overstated how imperative it is to properly rotate these fungicides to delay the development of pathogen resistance. Should 2020 take the same direction as the past few growing seasons, the pathogens most at risk for resistance will be spreading themselves far and wide to wreak havoc on high-amenity turf. And while innovations may someday provide superintendents with their own Winchester Model 1892, until then, rotation and IPM are the keys to keeping fungicide resistance at bay.

Brian Aynardi, Ph.D., is the Northeast research scientist for PBI-Gordon. Aynardi holds a Ph.D. in plant pathology from Penn State University, where he developed conventional and quantitative PCR detection methods for Sclerotinia homoeocarpa, the pathogen that causes dollar spot of turfgrass.