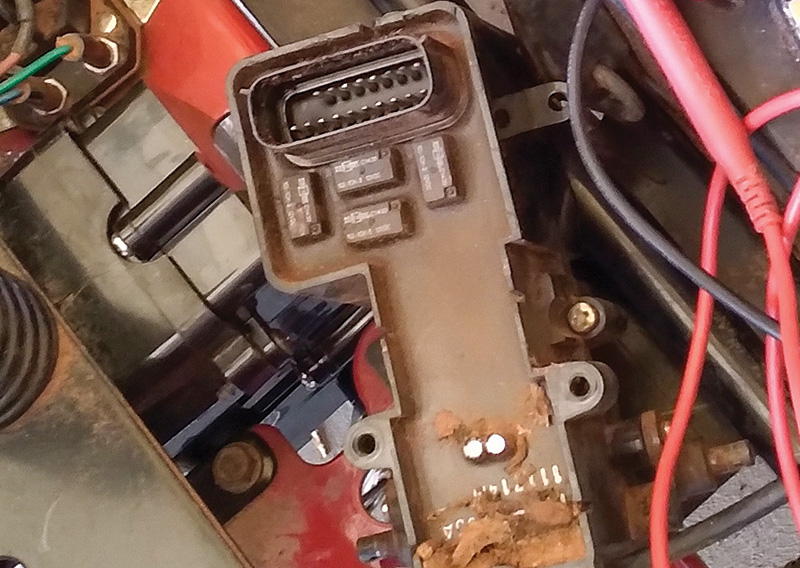

A disassembled Toro TimeCutter SWX5050 brake boxPhotos by Scott R. Nesbitt

Here’s hoping this can help cure the operation problems on Toro and Exmark mowers that have a brake box module that increases safety by replacing most of the mechanical safety switches with an internal computer.

Our machine was a Toro TimeCutter SWX5050 made in 2015. It has a steering wheel instead of control levers. Turn the starter key or pull the PTO switch, and you send a request to the computer, which decides if it is safe to do what you want. The box automatically

sets the parking brakes when you turn the key off.

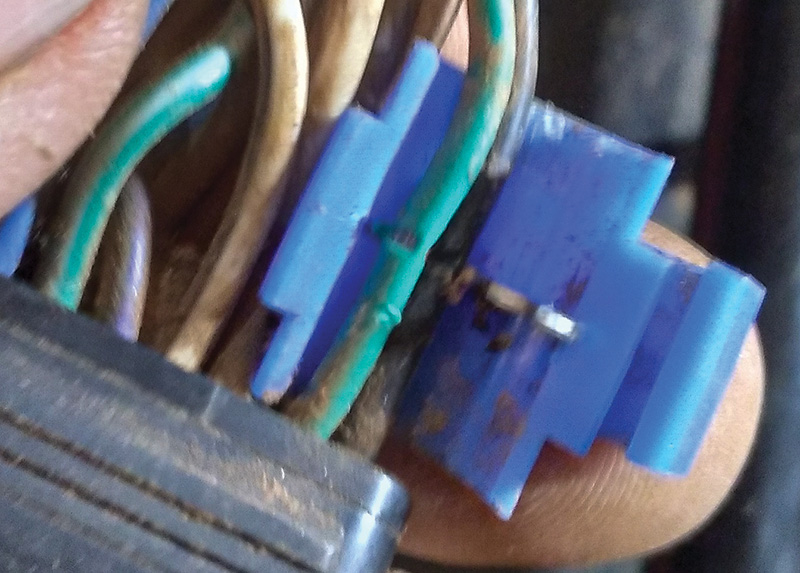

When the mower arrived, there was a “scotch-lock” jumper connecting the black box’s green wire that feeds the starter solenoid and a black chassis ground. This let you crank the engine under conditions the computer would not have allowed.

“scotch-lock” jumper

We removed the jumper and installed a new black box and cleaned a lot of “crusties” on the 18 pins in the socket. After three days, the mower was back with the same old problems — erratic starting, mower deck cutting in and out, parking

brakes not releasing. We traced the wire harness and components and found no problems like frayed insulation or pinched wires.

cleaned brake box socket

Too much skin was shredded putting the plug into the socket, since the box is mounted through the chassis main frame and under a brace that supports the seat. You use feeling, not sight, to wiggle and jiggle past the blade clutch and other obstacles,

and it’s hard to push the plug in.

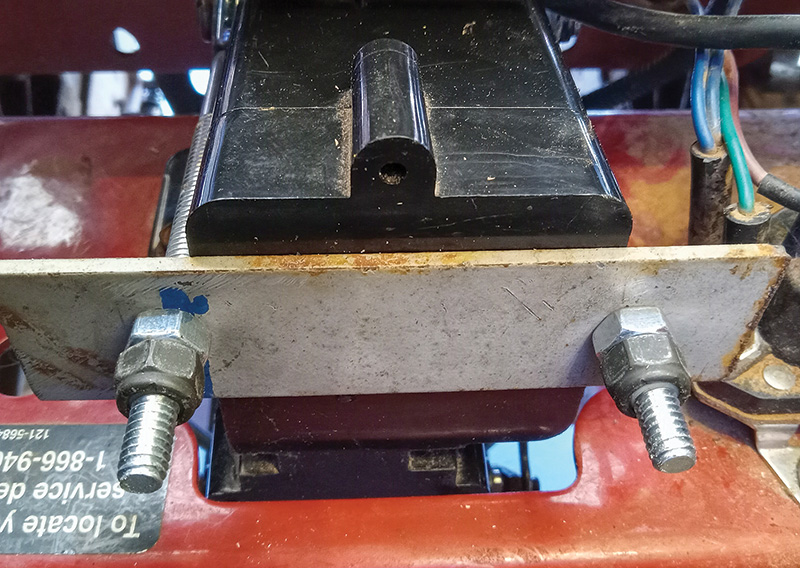

A crude hardware clamp restored all the mower’s functions. A 6D finish nail (1⁄8-inch diameter) was inserted between the two wire rows on the back side of the plug. Two ¼-inch-by-4-inch eye bolts grabbed the ends of the nail. A scrap

of steel was drilled to accept the threaded ends of the bolts. Nuts were installed on the bolt threads and carefully tightened until the assembly felt tight (photo below) and all the functions worked. Two plastic “ears” on the box had

to be removed so the eyebolts could hug the side of the box and pull the plug in straight. Those ears are supposed to receive screws that secure a plastic shield that’s intended to keep debris off the plug and socket. After inspecting the crud

on the old black box, we decided that shield wasn't very effective, so we decided to leave it off.

The reassembled brake box

There are at least three variations on the black box, with different numbers of pins in the socket. Though we don’t know if they can all be revived with a clamp, it’s not expensive to give that a try.

Scott R. Nesbitt is a freelance writer and former GCSAA staff member. He lives in Cleveland, Ga.